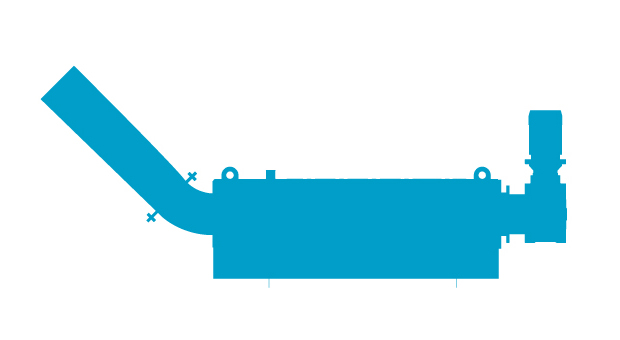

Rotapak 250

Renowned for its simple yet effective and efficient design, the Rotapak 250 works seamlessly with a variety of optional features to suit your smaller site in every detail.

- Handles screenings direct from the screen or conveyor

- Suitable for sewage or sludge

- Returns filtrate to main channel (normally gravity-fed)

- Mild steel body

- Maximum handling capacity 2 m3/hr

- WIMES 6.03 Compliant

The Rotapak 150/250 or 400 are compacting machines. After the solids (screenings) have been separated from the waste water via a screen they are either fed directly or channelled into the Rotapak through a helical screw conveyor into the compaction area where the remaining water is squeezed out from the screenings and returned to the waste water flow. The solid blocks of screenings are then collected into a skips and processed.

Bespoke Longwood Products

Our products are manufactured to sizes specific to each application. We do, however, modify our designs to fit a wide range of water treatment applications. Longwood Engineering have manufactured products suitable for diverse industries such as whisky distilleries and abattoirs.

Our innovative, design led manufacturing enables us to provide these kinds of bespoke solutions with speed, efficiency and flexibility for a range of markets. Why not contact us through the contact form or call us on 01484 424545 to discuss your project.